Standard Test Packages and Specialty Tests

LubeWatch Oil Analysis Program Provides:

Accurate results on six basic test packages and a wide variety of specialized testing procedures Reliable interpretation of test results and actionable recommendations based on the data 24-hour turnaround of tests and analyses indicating (after receipt of the lab) with maintenance recommendations via phone, fax or e-mail in 90 percent of cases Advanced technical services including component failure and/or wear particle analysis Expert training and in-field counsel and support Cost-effective standard and specialty tests Added assurance of oil and system integrity when running on an extended oil drain interval program

Add LubeWatch To Your Maintenance Program

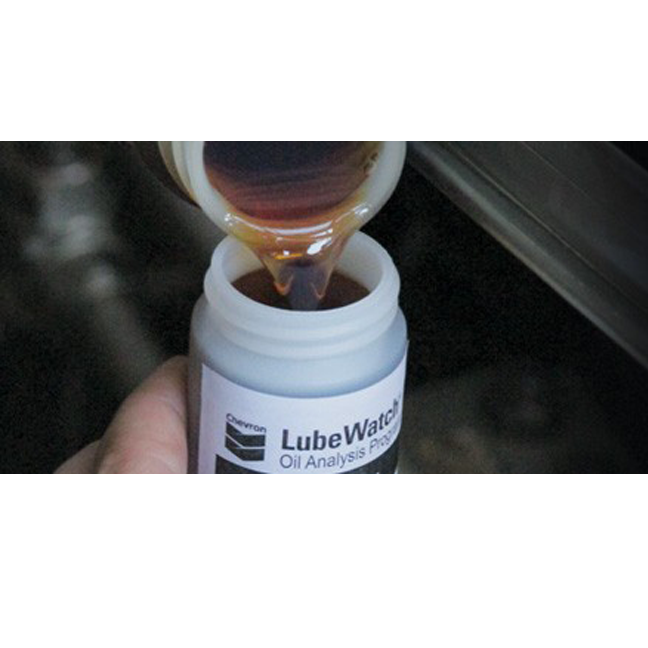

Submitting oil or other lubricants for LubeWatch oil analysis is simple. Contact your Chevron representative to find out how to contact the LubeWatch program lab nearest your location. The lab will set up your account and send a sampling kit to you. After pulling a sample, simply send it back with complete sample information to the lab in the LubeWatch mailing container.

Reliability is a Commitment

Building reliability into day-to-day business operations takes commitment. We should know. At Chevron, we’ve created a corporate culture that revolves around safety and reliability. We combine that with our legacy of industry-leading innovation in product formulation. Operating safely and reliably is an extension of who we are, and it sets us apart from lubricant suppliers that just talk about reliability. At Chevron, we live it.

Monitor Equipment Performance

LubeWatch oil analysis enables you to track the performance of equipment that is the lifeblood of your business.

Through regular oil analysis, equipment life and oil replacement intervals can be optimized and lubricant needs can be identified, and the changing environment within the equipment can be monitored. This knowledge helps in the precise scheduling of maintenance work that can reduce downtime or even eliminate the risk of catastrophic failure.